Automotive

Perfectly shaped functionality. With safety in mind

At SIMON Sinterlutions, we have decades of extensive experience, particularly in the automotive industry. Here, we manufacture molded parts such as gears or bearings according to specific customer specifications, which have significant advantages over other molding processes in terms of precision and reproducibility. These include, for example, functional components for electric motors, transmissions, steering systems and seat adjusters; but also safety-relevant components such as components for seat belt buckles or truck brakes.

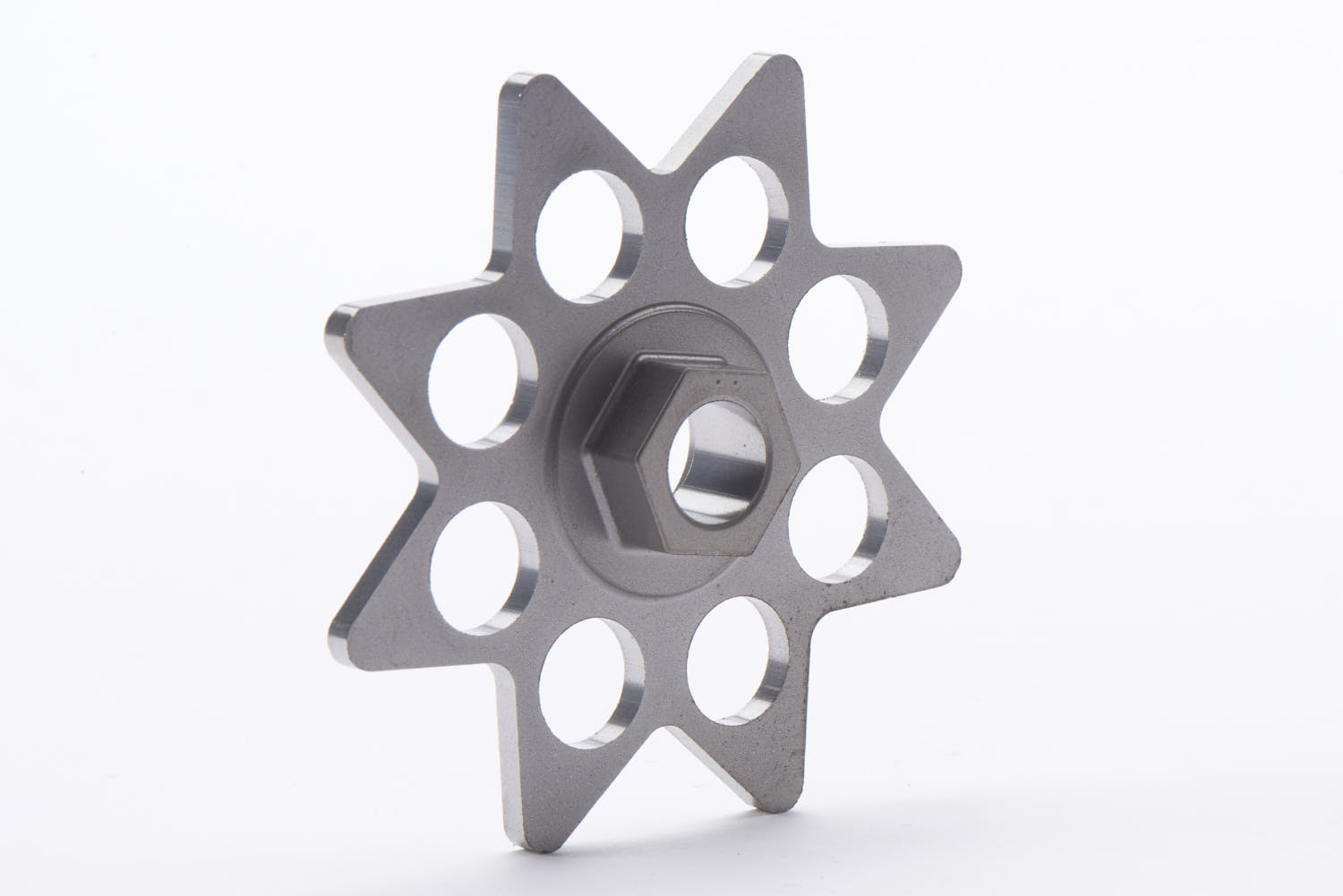

POWERTOOLS

Precision power for your “tools”

Various solutions from SIMON Sinterlutions are also used in numerous products in the power tools sector. The advantage of the high-precision molded parts, gearings and bearings we manufacture is that they can be optimally adapted to the respective requirement. They can be found in a wide variety of products from leading suppliers; for example, in chainsaws, leaf blowers, cut-off grinders, brushcutter and hedge trimmers.

DRIVE COMPONENTS

Perfect solutions for drive and motion

Customized sintered products are becoming increasingly important in series-produced drive components for intralogistics. For example, SIMON Sinterlutions products are also used in planetary gears of drive rollers at parcel distribution points. With our precision and the high reproducibility of our products, we also develop the perfect solution for you.

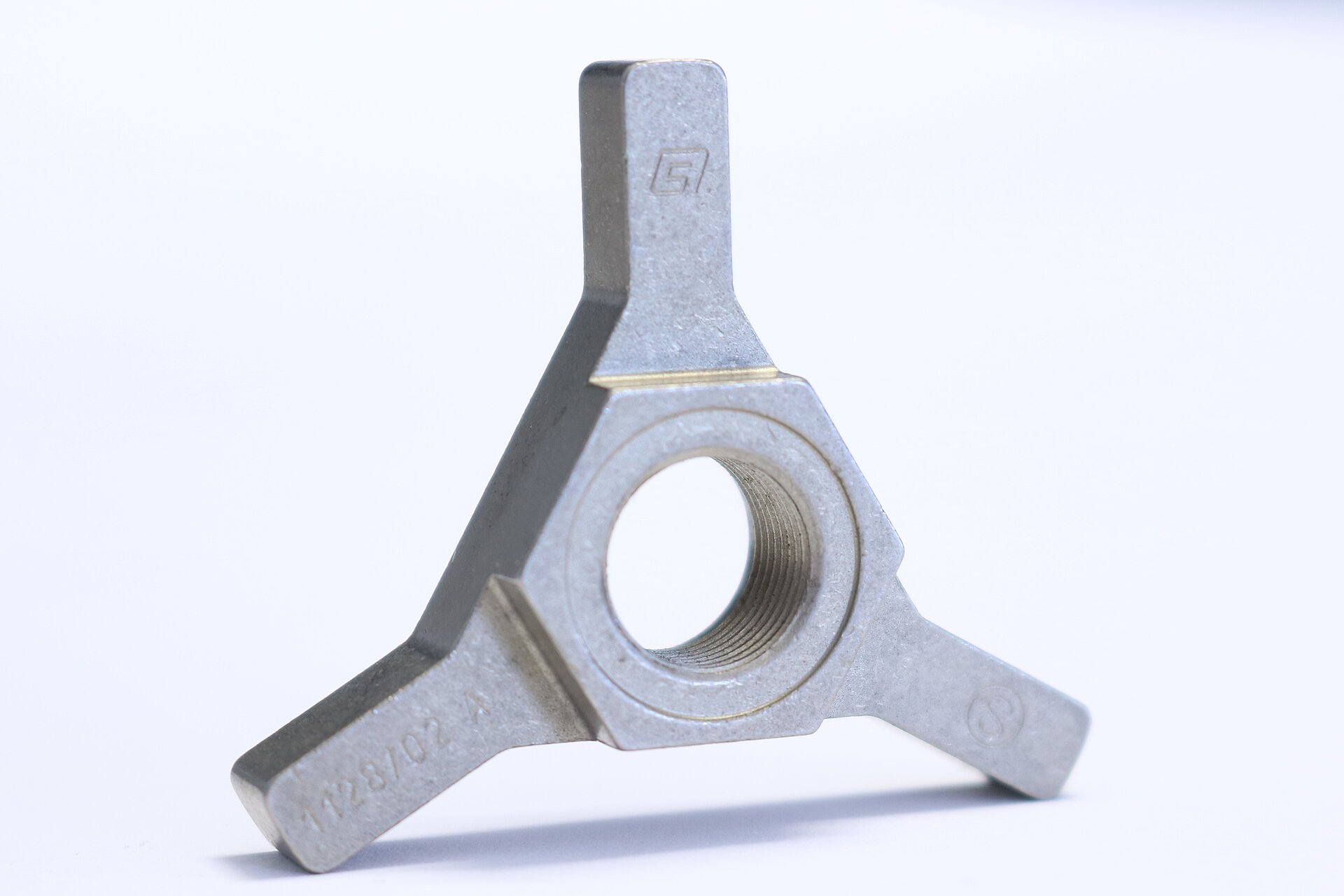

FITTINGS FOR THE CONSTRUCTION AND FURNITURE INDUSTRY

Our quality – for your protection and comfort

Our customized sintered products are particularly suitable for safety and comfort applications. Whether bolts, serrations or detents – high quality and consistent reproducibility even for medium-sized series ensure that our solutions are increasingly being used in window and door locking systems, as well as furniture comfort applications.

MACHINERY

Safety you can truly rely on

Especially in mechanical engineering, quality “Made in Germany” is still a convincing argument. The same applies to our extensive support when it comes to matching components precisely to customer benefits. This is precisely why the plain bearings with permanent lubrication properties that we manufacture are so much in demand in control and automation technology: Because they are particularly safe.