Corporate profile

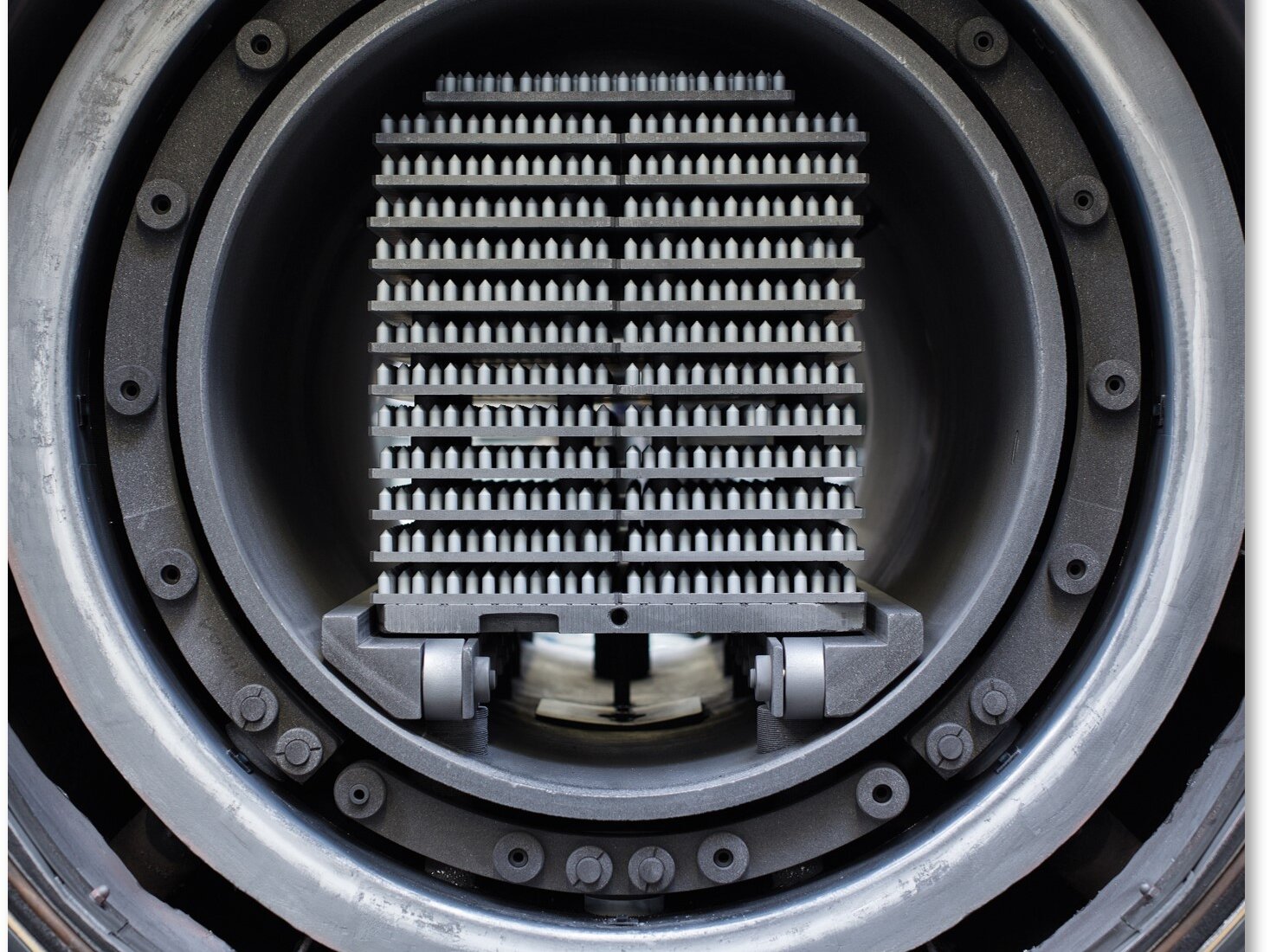

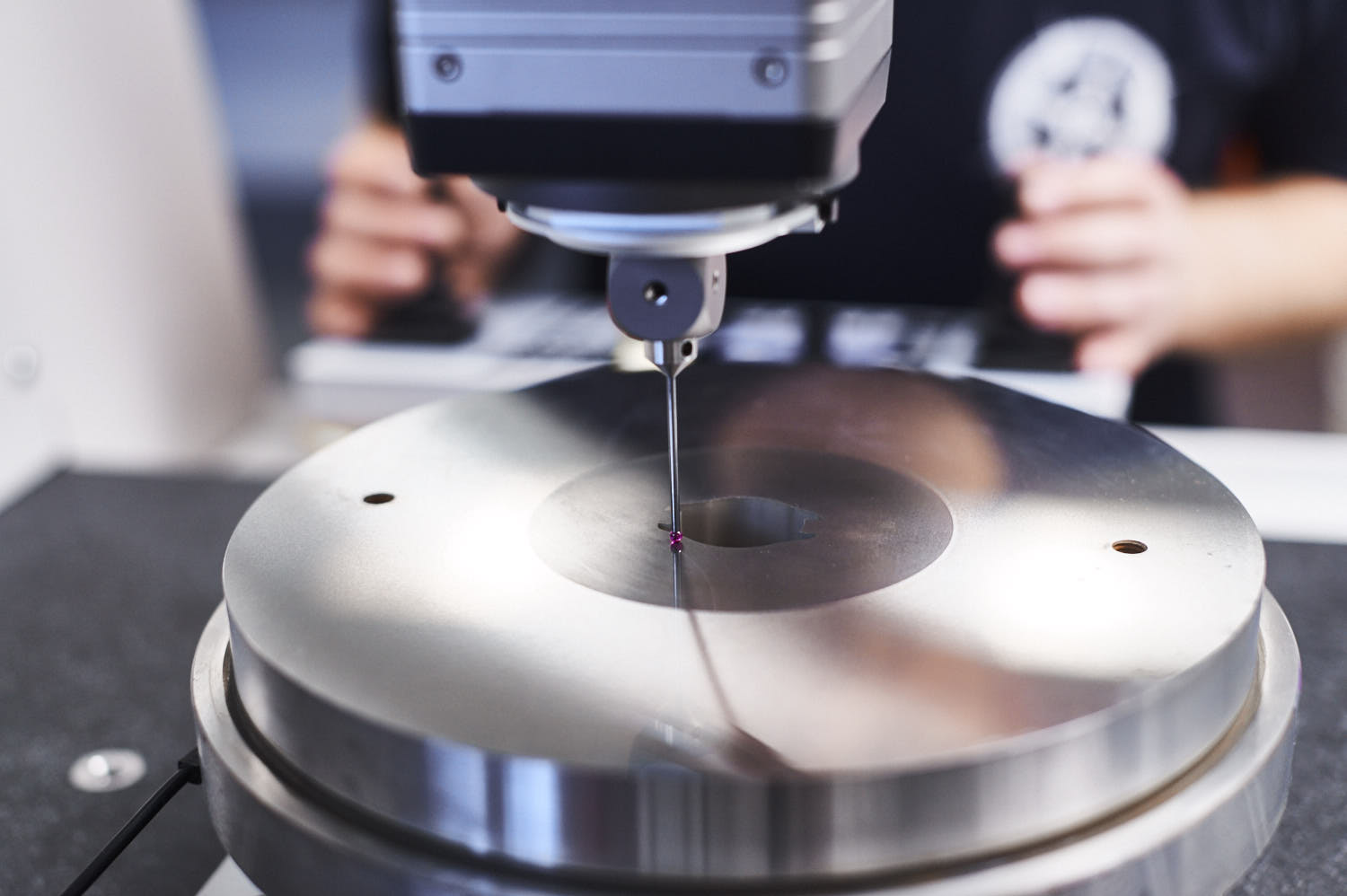

Finished components for a wide range of requirements

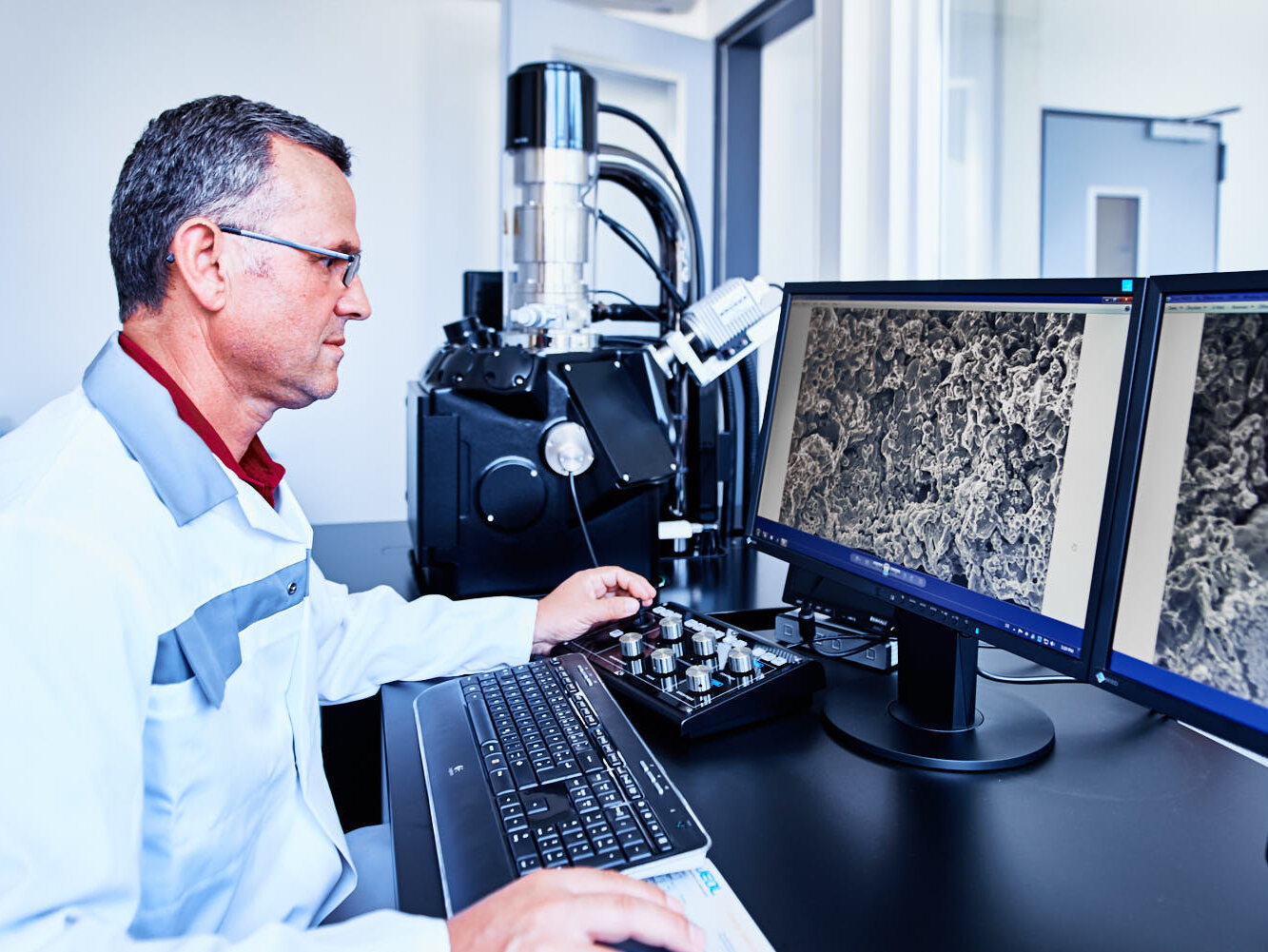

At SIMON Sinterlutions, we use special pressing and sintering processes to manufacture high-quality, complex parts as ready-to-install components and assemblies. Our products are used successfully all over the world: in the automotive industry, power tools, drive components, hardware components for the furniture industry, mechanical engineering and numerous other highly specialized fields of application. With our high quality solutions we are your perfect partner for developments in the field of component optimization.

In the area of series production of functional components and assemblies, the sintering process represents a worthwhile alternative for many common technical applications. It offers numerous advantages, particularly in terms of resource conservation, economy and savings in material and weight. SIMON Sinterlutions has extensive experience in all processes such as calibrating, surface treatments, annealing and mechanical machining and is your specialist for small, medium and large series for products made of iron powder.