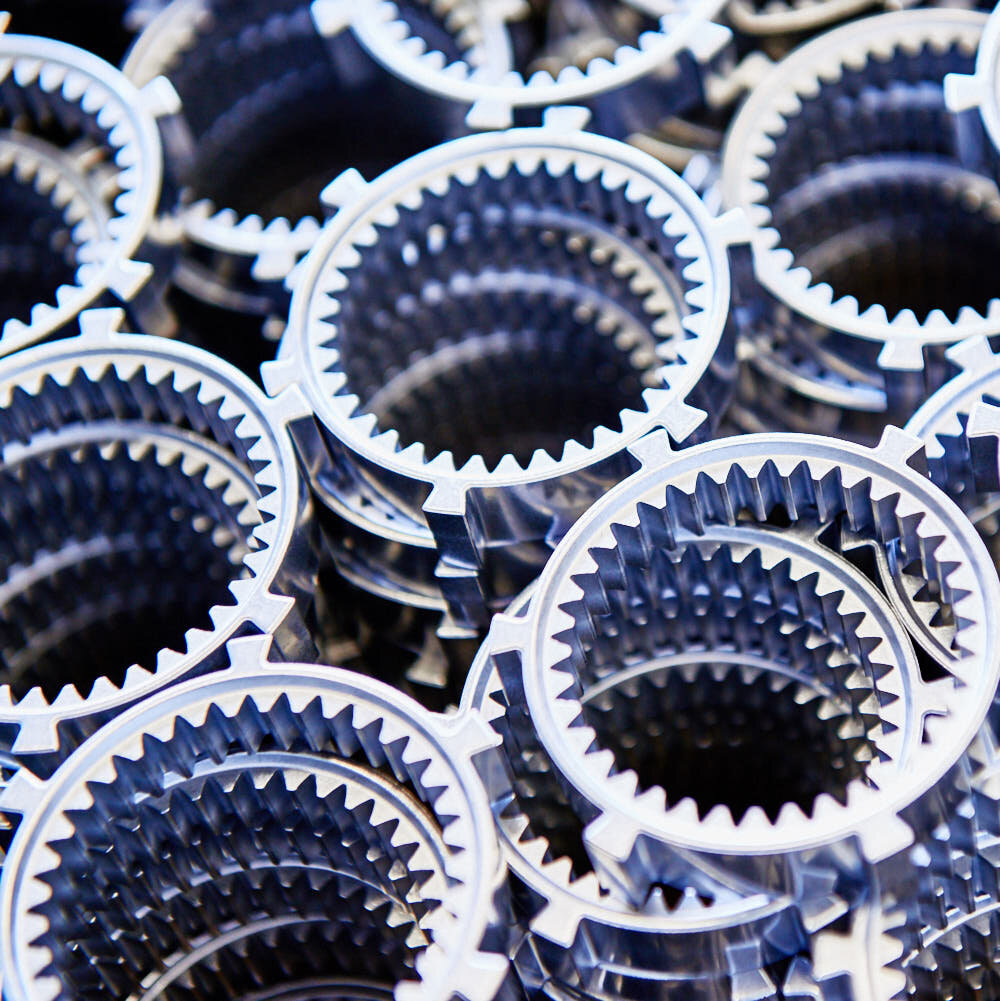

At SIMON Sinterlutions, we use sophisticated pressing and sintering processes to produce complex parts as components ready for installation. We use metal powder for production. In addition to the automotive industry, our high-quality products are used in numerous sectors: as power tools and drive components, as fittings for the construction and furniture industries, and in many other highly specialized fields of application. With our many years of experience in the development and optimization of sintered components, we are available to you as a partner at any time and in a comprehensive manner.

Expertise

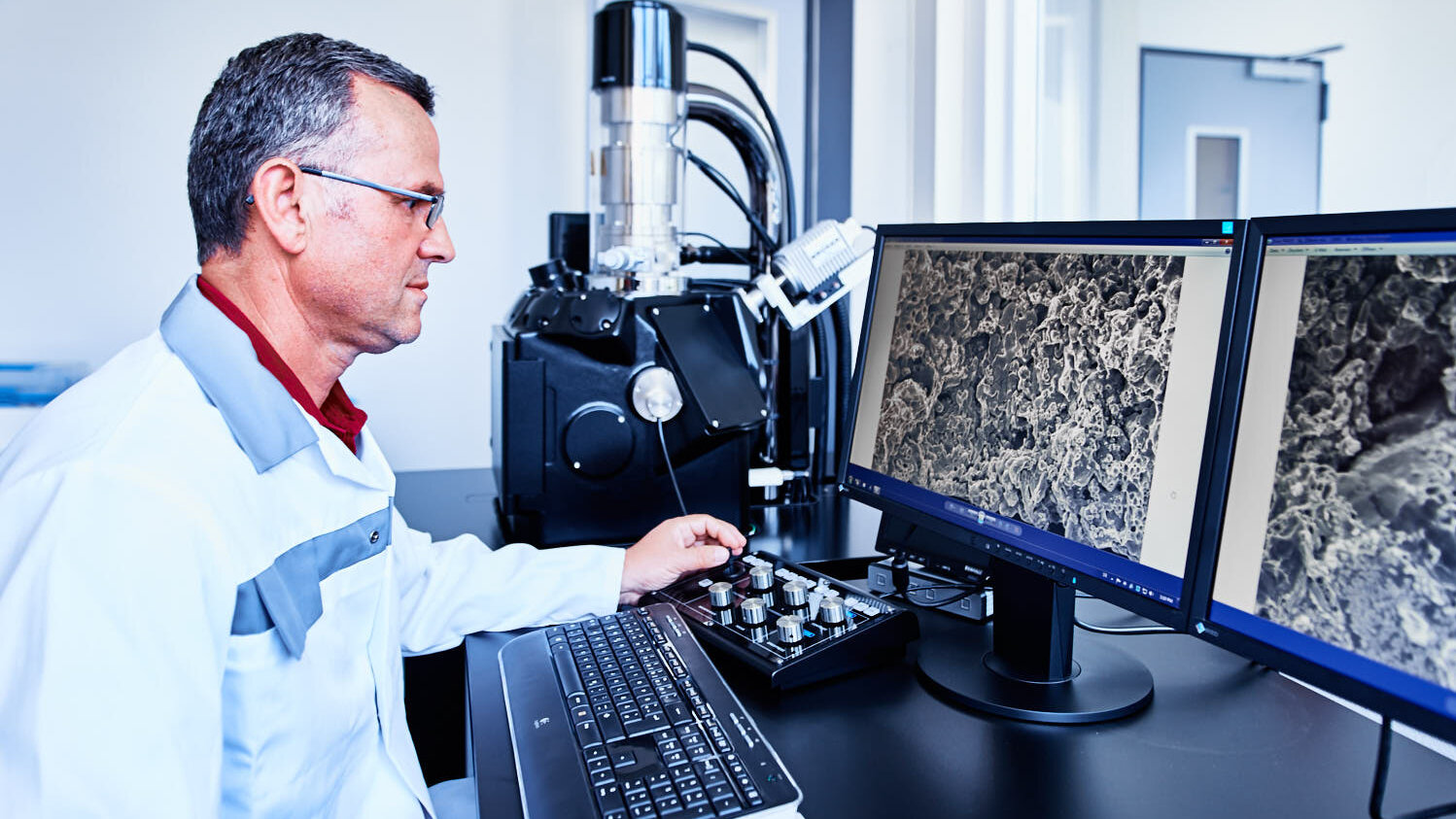

Application specific and reproducible

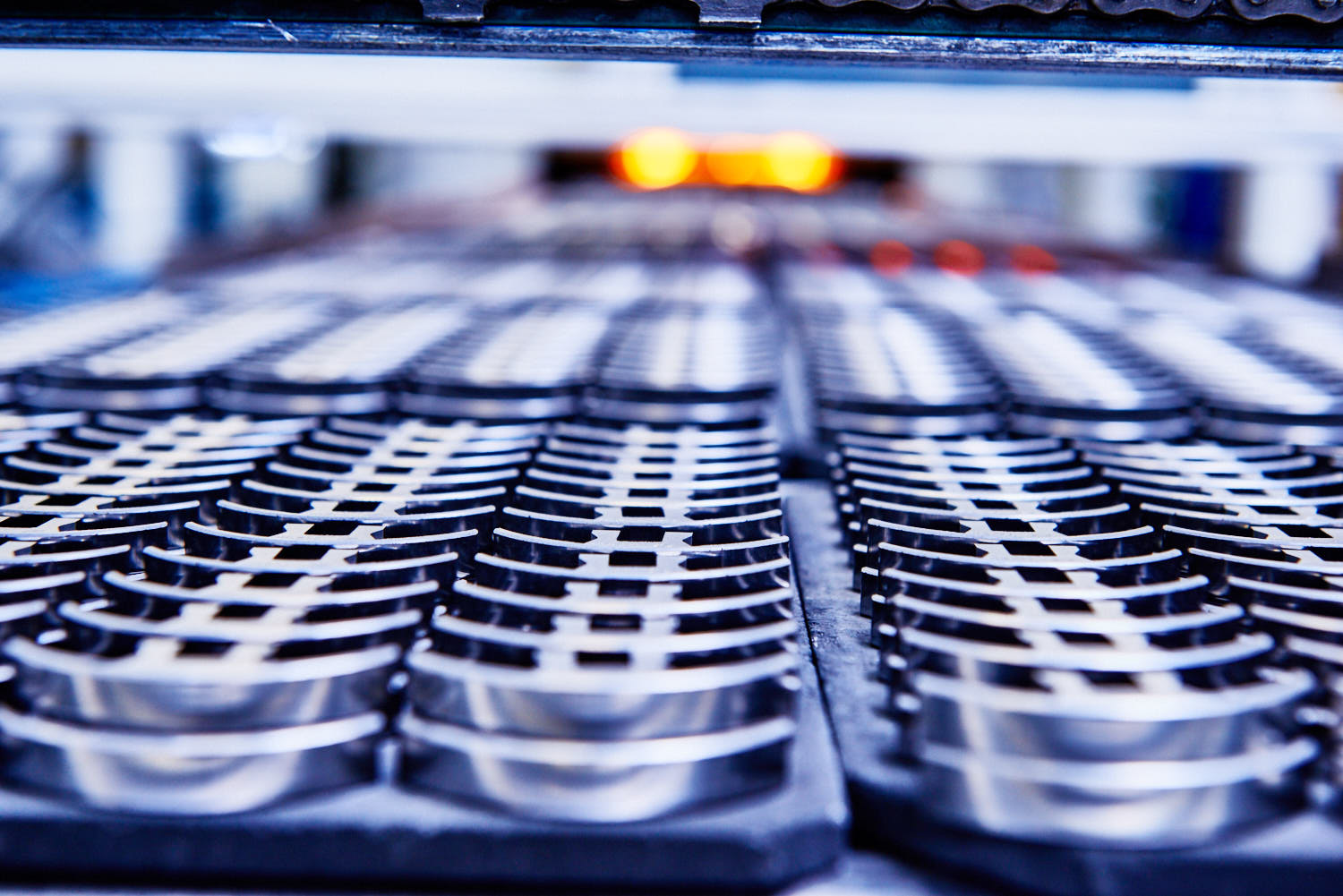

SIMON Sinterlutions is your reliable partner for the development, production and assembly of assemblies made of iron powder for a wide range of requirements. With our mechanical, hydraulic and servo-electric multi-plate presses, we achieve not only great design freedom but also high repeatability. We already provide you with comprehensive advice on the selection of materials, in order to achieve the optimum product properties you require. During the entire process, our project management accompanies you – from the development phase to the SOP.

Whether as simple sintered bushings, highly complex molded parts or entire assemblies: SIMON Sinterlutions’ products are used successfully all over the world in a wide range of industries. The pressing and sintering process offers significant advantages over other manufacturing processes, particularly in the series production of metallic components with demanding geometries. These include high precision and reproducibility, as well as lower component weight compared to solid steel. In addition, there is enormous potential for savings – if only because reworking processes are no longer necessary.

SIMON Sinterlutions has decades of experience in the following application areas:.

- Automotive industry

- Powertools

- Drive components

- Fittings for construction and furniture industry

HIGH DEGREE OF MATERIAL UTILIZATION – MINIMAL WASTE

Sustainability.

Sustainability begins with the conservation of resources: Particularly with regard to material and weight savings, the sintering process offers an attractive, highly economical alternative to machining processes. The production of sintered parts generates practically no waste, as the raw material utilization is almost 100%.